Leonidas Kehagias

Leonidas Kehagias

At a time when feeding the world’s population appears increasingly difficult due to extreme weather and limited space for farming in densely populated areas, innovation lies in both conventional and unconventional places.

In 2022, 735 million people faced acute hunger and the United Nations projects more than 600 million people will still face hunger by 2030. Still, when so much of the news surrounding food insecurity focuses on threats and losses, it’s important to keep in mind that people and organizations of all kinds are actively working to find innovative ways to continue bringing food to tables around the world.

The University of Arizona and the Bayer Marana Product Development Center are both places where new innovations are being tested that could drastically change the way food is produced. Freight Farms at the University of Arizona and short-stature corn at Bayer are two different technologies that illustrate the potential of new innovation, as well as the challenges associated with scaling them to increase production.

When one thinks of farming, expansive fields traversed by tractors might be one of the first images to come to mind. Conventional means of food production have largely become synonymous with a need for ample growing space and water as well.

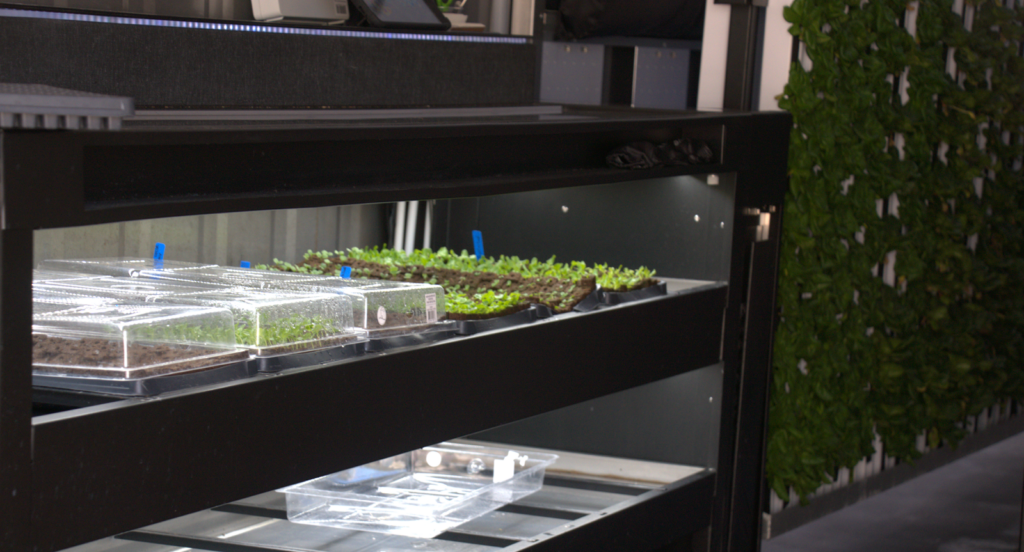

The concept of growing some vegetables inside shipping containers, however, offers a very different image of what farming can look like. At the University of Arizona’s Biosphere 2 research facility in Tucson, Arizona, researchers are working with a company called Freight Farms to make this concept a reality.

Freight Farms takes empty shipping containers and installs vertical hydroponic farms within them. These containers can be used to grow certain types of produce in enclosed environments in locations all around the world.

“They make these in such a way that they are essentially plug and play,” said Jason Deleeuw, a terrestrial biome manager who runs the Freight Farms unit for the University of Arizona. “If you can get power to them, get some water, you can go ahead and plant plants in them.”

The Freight Farms unit at the University of Arizona currently grows lettuce and can house about 1,100 plants at a time. Seeds are first planted in the nursery portion of the container, before being transferred to vertical growing panels in the cultivation area as they get larger.

Deleeuw said the Freight Farms container at the University of Arizona only uses about 0.3 gallons of water per head of lettuce, where conventional methods would require three to five gallons of water per head. On average, the entire cargo container uses about five gallons of water per day.

Aside from consuming less water per head of lettuce, Freight Farms can potentially conserve space relative to conventional lettuce farming. Deleeuw said the University of Arizona’s Freight Farms unit can produce the same amount of lettuce in a single shipping container that conventional methods would require 2.5 acres to grow.

However, despite these benefits, challenges do exist that prevent Freight Farms from scaling in their current form.

“They’re tremendous energy hogs,” Deleeuw said. “It uses somewhere around 220-250 kwh a day, which is a lot.”

For comparison, the average American household in 2021 used just 29 kWh per day.

High startup costs also pose a barrier to widespread utilization of Freight Farms, as the unit at the University of Arizona initially cost $150,000, Deleeuw said. While many educational institutions around the world are investing in Freight Farms, Deleeuw said he does not see them as accessible to the average consumer at their current cost.

While Freight Farms may not currently be able to sustain heavier, staple crops like rice, wheat, and corn, they do show promise as a way for smaller commonly used produce such as lettuce, strawberries and various herbs to eventually be grown within urban communities.

Further progress is certainly still needed to address the high energy consumption and startup costs of Freight Farms, which is what the researchers at the University of Arizona are currently investigating.

Not far from the University of Arizona in Marana, Arizona, the biotechnology giant Bayer is working on creating a new type of corn to improve the yields of conventional agriculture production.

Known as short stature corn, the new crop has been bred to stand seven feet tall when fully grown. Traditional breeds of corn on the other hand stand roughly between nine and 12 feet.

“[Some] of the benefits of short corn [are] it has a stockier, lower center of gravity, less wind damage, things like that,” Brett Sowers, Bayer Marana’s site enablement lead said.

Sowers said the taller builds of traditional corn breeds increase the likelihood that corn will be irreparably damaged during instances of high wind. The taller the corn is, the more easily it is weighed down by the ears of corn it carries when storms occur.

Short corn is not just more wind resistant but also easier for farmers to manage. Sowers said the smaller size makes it easier for farmers to apply fertilizer and other crop inputs.

Corn that is more wind resistant and easier for farmers to care for can lead to a greater crop yield overall, since ears of corn are more likely to remain attached to their stalks for the entirety of the growing season. Sowers said that this, combined with the greater likelihood of stalks remaining unbroken, leads to better harvests stemming from the short corn.

Ricardo Rodriguez, senior operations lead at the Bayer Marana facility said another advantage of the short stature corn comes from the amount of water it consumes relative to more conventional corn breeds. “Thanks to the foliage of these plants, it is possible to create a dense coverage which allows short stature corn to keep moisture in the soil for 10 days longer than conventional corn. So there ends up being less water used during the production cycle,” Rodriguez said.

Stalks of short stature corn can be planted closer together which leads to more corn being planted on less space, something that can be beneficial to corn growth yet detrimental to soil health. Rodriguez said that the more closely planted corn leaves little to no room for intercropping, the practice of growing two or more crops in close proximity to one another which adds nutrients to the soil and helps prevent erosion.

As with Freight Farms, there are other challenges to the applicability of short stature corn.

Sowers said the research at Bayer’s Marana plant is currently focused on the development of short stature corn that will be primarily used for things like animal feed and ethanol production. Corn geared toward feedstock and ethanol production is not conducive to human consumption due in part to its harder texture and lack of sweet flavor.

Bayer sites around the world are working to increase the resiliency of other staple crops such as wheat, cotton, and soy, according to Ryan Mertz, plant establishment lead at Bayer Marana.

Bayer expects the corn seeds to be more widely accessible during the 2024 growing season.

Growing smaller produce in shipping containers and breeding short stature corn are two distinct innovations that both seek to develop better ways of growing food in a changing climate. While new projects like Freight Farms may be necessary to bring fresh produce to places it previously could not be grown, the resources of large scale actors like Bayer will also be important in maintaining and improving staple crops that so many already depend on.

Each of these innovations seek to fill respective gaps in the accessibility and resiliency of crops by improving existing agricultural frameworks or by developing completely new farming techniques. At the end of the day, our agricultural future will be secured using vast combinations of these techniques and others, each addressing the needs of stakeholders big and small.

“Food is about everything,” Holly McLaughlin, PacWest sustainability specialist at Bayer, said. “You’re diving into the complexity, not only of it being interdisciplinary and systems thinking, but it’s personal, spiritual, cultural, ecological, biological…you really can’t look at food challenges in a vacuum.”