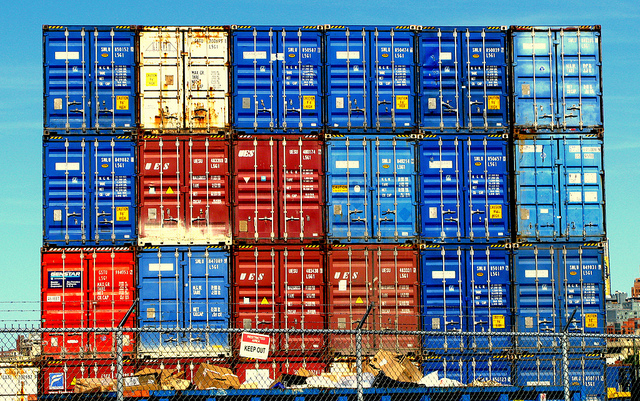

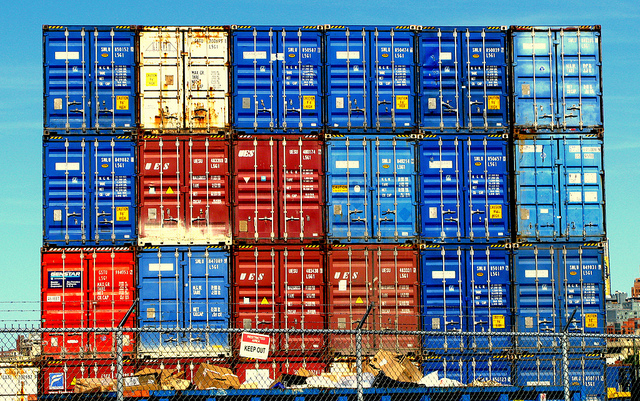

SpaceCube composite container

One of the largest modes of transporting goods has been steel shipping containers. They have a dead weight that must be added to the transportation and costs, they also must be transported empty using huge amounts of fossil fuels adding to the carbons emitted to the air. If the containers weigh less it will allow for the internal cargo to increase, thus reducing the emissions used to transport each ton of cargo and ultimately lowering the carbon foot print.

I have a patent pending CSE certified composite container system that weighs a minimum of 30% less. This will allow the ships, rail roads and trucks to transport up to 2500 lbs more per 20 ft container. We have gone one step further wand are in the process of making a collapsible container, this will fold down to 25% of the original size. This will allow the 4 collapsible containers to be shipped in the same space of 4 steel containers. Example; if a trailer truck weighing 80,000 lbs carries 2 containers fully loaded and travels 500 miles to deliver it, it will unload it and return empty or go on to pick up a new load. If you did this 5 times to the same site you would have 10 empty containers to return back to port. or 5 truck loads with no benefit except for the empty containers. our system would allow one truck to return all 10 containers in one trip. This will revolutionize the shipping industry.

The fact that one ship carrying 4000 loaded containers can come back with 4000 collapsible containers and 3000 loaded containers. thus having a significant lower carbon foot print by saving the ships large amounts of fossil fuels and increasing the load potential. I am presently going to open our manufacturing facility in Tennessee and creating up to 300 jobs to produce these containers. It is currently one of the only container manufacturing of this type container in the USA. We have 6 other uses that we will unveil this year from our new facility, all with the potential to reduce the use of fossil fuels.