Planet Forward Staff

Planet Forward Staff

When people think of the sorts of cutting-edge technologies that are changing the world, they tend to think of atom colliders, Elon Musk and Silicon Valley. The popular imagination may think of agriculture as Mom and Dad with a pitchfork, but today’s Nebraskan corn farm is probably the furthest thing from the average arm-chair-futurist’s daydreams of farming reality.

And agriculture has some of the most important innovations in the past 100 years. After all, the world’s population has exploded in the past century. Agriculture has had to adapt rapidly to feeding a more crowded planet – and it must continue to do so.

A study conducted by the United Nations Food and Agriculture Organization found that a 70% increase in agricultural productivity will be necessary to keep the world’s population fed in 2050, and meeting that demand is not just a matter of finding 70% more land to farm since most of the land on earth that can be used for farming already is being used. Then there are the environmental concerns. The global green caucus worries that this increase in productivity will come at the cost of more water, more land, and higher emissions. Add up all these woes and you’ll come to find that we’re placing a hefty bet on that Nebraskan corn farm finding a way to increase productivity in the face of environmental concerns and a growing population.

Maybe it’s time to take a closer look at this allegedly low-tech operation.

Scott McPheeters lives on his Gothenburg, Nebraska, family farm, bordered by breathtaking sandhills carved from the earth by glaciers and wind. The farm has around 3,000 acres of row crops. Most of those 3,000 are dedicated to corn, and most of that corn goes into Fritos. (If you eat a Frito chip west of the Mississippi, there’s a better than good chance that the corn used to make it came from Gothenburg.) McPheeters is also keen on ethanol, and even serves as the vice chair on the state’s ethanol board. He sings the praises of the biofuel to whomever is willing to listen, seeing it as a path to sustainability and American energy independence.

The corn that comes back from ethanol production is used to make starches, sweeteners and road de-icer. There is talk of making ethanol out of switchgrass, since switchgrass grows up huge and has lots of sugar and could be more sustainable than corn-based ethanol. But scientists haven’t developed the enzymes necessary to ferment switchgrass into ethanol — at least not yet.

“It used to be that a farm would have ‘a cow, a sow, a plow and an 80.’ Like… 80 acres,” McPheeters says. “So if it was true that there would be 80 acres per family… (and if) you had 3,000 acres, you would maybe need 40 people.”

The 10 families of four it would have taken to run McPheeters’ farm a hundred years ago would have used horse-drawn equipment for planting and plowing, and a hand crank to strip field corn to be used for animal feed from the cob. During planting and harvests seasons, the work days may have been 14 to 18 hours long.

After World War II, when many midwestern farmers adopted combines and tractors, the number of families necessary to run a McPheeters’-sized farm dropped to around five. That’s about 20 people total.

Today, including McPheeters himself, five people work full time on his farm. Two of those people are his sons, one his son-in-law. McPheeters says he can operate with such a small team thanks to the technology that’s now commonplace on farms.

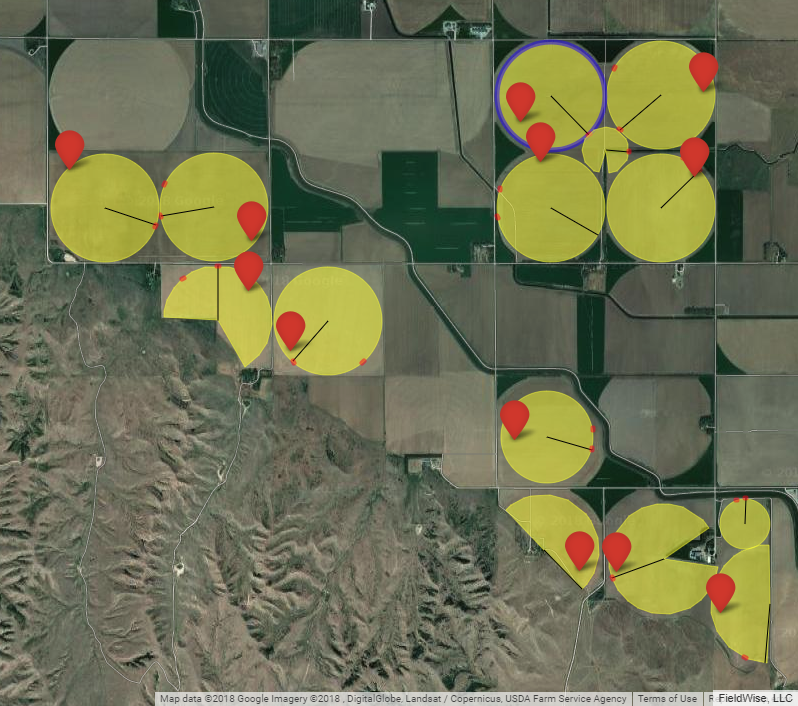

Drones, for instance, can be used to run diagnostics on central pivot irrigation systems — an enormous row of sprinklers that rotate around a central point, providing water to a circular portion of crops. McPheeters said their drone could alert the team to plugged outlets in the pivots and detect problems with tires and drive shafts. Meanwhile, the pivots themselves could be controlled via iPad. Drones provide significantly better imagery than satellite technology, though there are still regulatory concerns.

Using apps and iPads to monitor crops has become crucial for farmers, especially when it comes to water.

If you took all the water under Nebraska and put it over Nebraska, the whole state would roughly be a 42-foot-deep lake, according to math and hydrogeology. (Don’t ask.)

But despite the state’s position over the gargantuan Ogallala Aquifer, Nebraska is bone-dry at the surface, with 23.6 inches of rain per year. Compare that to Arkansas (50.6 inches per year), Rhode Island (47.9 inches per year) or, if you’re feeling dramatic, Hawaii (63.7 inches per year) and the importance of efficient irrigation becomes apparent. Over-watering is wasteful and can be damaging. Under-watering can be a disaster.

To make sure every corner of the farm is properly watered, McPheeters embeds 4-foot-long “soil sensors” deep in the ground. The sensors are connected to transmitters that communicate with a software called FieldWise. FieldWise displays a representation of the crops and details on their conditions on McPheeters’ computer.

Both the monitors and the transmitters are powered with energy from solar panels.

McPheeters stresses that the transition from one family having “a cow, a plow, a sow and an 80” to one family managing 3,000 acres of highly productive farmland didn’t come in a straight curve. A huge change came in the past 10 to 15 years, for instance, when global positioning became viable. With GPS, McPheeters can know exactly where a piece of equipment is in the field at any given moment and remotely ensure that it is doing what it needs to be doing, down to the square foot or an individual plant. Seeding units can sequence off and on to prevent over-seeding. Equipment can run on autopilot for 24 hours a day.

GPS is proof positive that a single new technology can have a bombshell effect on how agriculture is practiced — and McPheeters has an inkling as to what form the next seismic shift in farming might take.

“You may or may not want to hear this,” McPheeters said. “But I think it’s genetic engineering.”

Within the Gothenburg city limits is another plot of land that at first glance doesn’t appear all that different from McPheeters’ family farm. Upon closer inspection, it turns out to be a 324-acre science experiment.

The Water Utilization Learning Center is managed by Monsanto, a biotechnology company that you’ve probably either never heard of or have already made up your mind about. Documentaries like Food Inc. portray Monsanto as the Big Bad Wolf of big ag, but however you may feel about the company, it’s clear that some of the most groundbreaking innovations in agriculture come from their work.

The Learning Center draws people from all over the world, and tours are given regularly. Although it is made by another company, the never-browning arctic apple is touted to one tour group as an example of the triumphs of genetic modification. Arcane crops like bloody butcher corn (whose kernels are alternately inky-black and the iron-red of Martian mud) are presented to demonstrate corn’s genetic diversity.

Every season from April to October, the Learning Center conducts between 60 and 70 studies. Problems they hope to crack open include finding a way to double yields within the next 12 years, producing seeds that require fewer resources to grow to maturity and developing crops resistant to everything from Roundup to rootworm. (Rootworm larva probably cost around $800 million a year in yield loss according to the USDA.) They also research ways to manage crop-damaging diseases like Goss’s wilt, stalk rot and anthracnose.

Monsanto gets creative to mimic adverse conditions for their studies. To approximate hail damage, they use a string weed trimmer. To simulate drought, they have a massive rainout shelter, a sort of retractable barn that extends to shield the crops when it rains.

At any given time, at least 10 to 12 of the studies being conducted by the learning center focus on water and irrigation. To deliver specific amounts of water to different studies in tightly controlled experiments, they use a variable rate irrigation system which applies GPS coordinates to deliver calculated dosages of water to each plot. Studies are separated into groups by 20- to 40-foot borders to prevent cross-contamination.

“(We can) choose through genetics different hybrids that will produce better crops for the future,” says a Monsanto representative. “We look at water use efficiency, economics and sustainability of the cropping system in addition to yield.”

The next frontier on genetic-level agricultural innovation is likely to take the form of CRISPR (which stands for “Clustered Regularly Interspaced Short Palindromic Repeats,” sort of the “Lucy in the Sky with Diamonds” of biotech acronyms). CRISPR is a tool for editing genes, not to be confused with genetic engineering, which refers to transplanting a gene from one organism to another. Gene editing techniques like CRISPR have the double-benefit of allowing for more subtle alterations in an organism and being free from genetic engineering’s bad press.

Of course not everyone thinks genetic engineering deserves the flak is has taken in the first place. Scott McPheeters for one thinks the controversy is overblown.

“For some people to say ‘oh my gosh, they’re gonna take a horse and make it into corn…’” McPheeters says. “No. With corn, maybe the stalk is great but it isn’t good for milling. Or the ear is really nice but the stalk or the leaves aren’t up right and it doesn’t catch as much sunlight. So what you can do is, you can pick the best things. Gregor Mendel did this with his peas.”

Regardless of how one feels about genetic engineering and gene editing techniques like CRISPR, it’s inarguable that they’re the bleeding edge of agricultural technology.

It is hard to imagine what this might mean for the future of a family farm like McPheeters’, or even to know whether the places where our food is grown in the future will even resemble farms as we know them. We can speculate as to what a family farm might look like in, say, 100 years, but speculation is just that. The farmer of a century ago never could have foreseen McPheeters’ 3,000-acre behemoth, watered by a tablet-controlled pivot irrigation system and harvested by a massive combine. They couldn’t have imagined Monsanto’s learning center, where crops are tweaked at the genetic level to withstand drought and disease.

Science fiction writers often see new technologies coming before even the scientists who ultimately develop them, according to University of Toronto professor Dena Taylor. They have imagined everything from utopian futures in which humans terraform other worlds with earthly vegetation (see: Kim Stanley Robinson’s Mars Trilogy books or the TV series The Expanse) to worst-case-scenarios in which agriculture falls short of the demands of population growth and people turn to desperate measures (see: movies like Soylent Green and Snowpiercer).

But it’s hard to find popular sci-fi that even begins to cope with the genetic engineering and gene editing of food in any substantial sense. Maybe that’s because techniques like CRISPR — developing in fast forward to match the demands of a skyrocketing population and a straining climate — make predicting the future feel like hitting a moving target. The only thing that seems certain is that whatever comes next will make drones, pivots, and global positioning look like a cow, sow, plow and an 80.